PRASHANT GALVANIZERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PRASHANT GALVANIZERS

Sub Station Structures

A List of the types of the supporting structures :

- Lightening Arrestor.

- Post Insulator.

- Beam.

- Current Transformers.

- Power Transformers.

Sub-Station Structures are used to support power grid components and electrical equipments. Sub-Station Structures shall be fabricated from latticed angles, Pipes, Plates … etc. A common definition for sub-station structure is an assembly of equipments.

Switchyard Structure is generally applied for the assembly of switches, power circuit breakers, buses and auxiliary equipment, which are used to collect power from the generators of power plant and distribute to the transmission line at a load point. As far as structures are concerned the terms, Sub-Station and Switchyard structures will be used interchangeably

Transmission lines are power lines typically with voltage at 66KV and above. Voltage than 66KV are usually referred to as distribution lines. Transmission Line Sub-Station Structures are to be used for protection of Sub-Station equipments. Shield wires may also used for communications.

Electrical clearances provides physical separation needed for phase to phase, Phase to Structure and phase to grounds air gap to provide safe working areas and to prevent flashover.

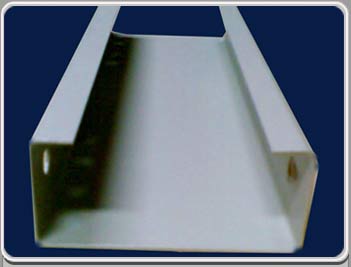

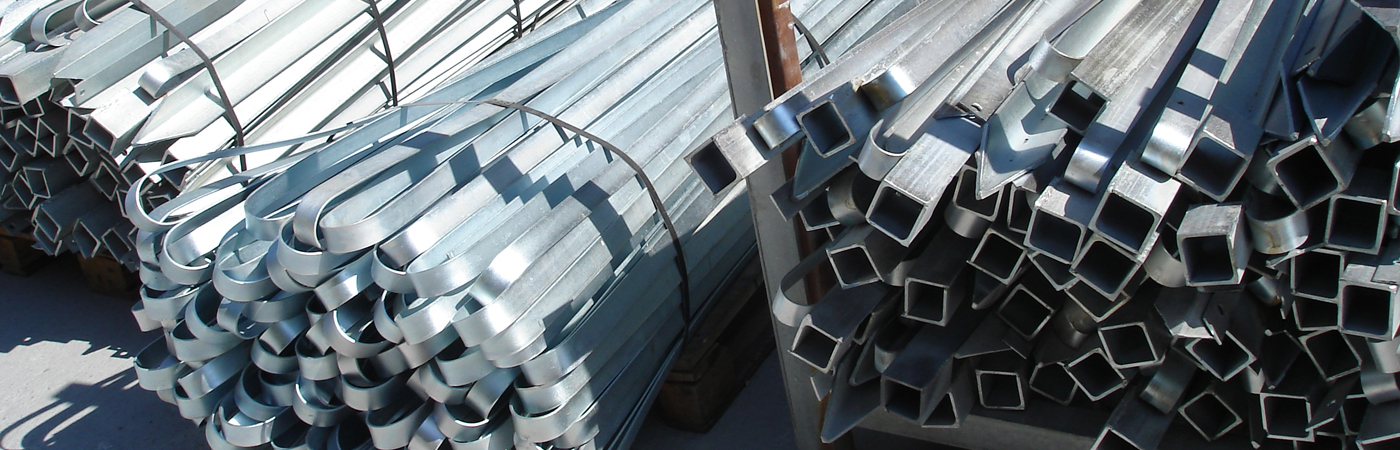

RAW-MATERIALS OF OUR PRODUCTS :

Generally we use M.S./Alluminium Sheets, Structural Forms viz. Angles, Channels, Beam, Plates, Flats, Rounds…etc. Zinc, Primers & Paints. All these we purchases from the reputed manufacturers/traders with required Test Certificates.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

- Visual Check Test.

- Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

- Adhesion Test as per IS-2629.

- Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.